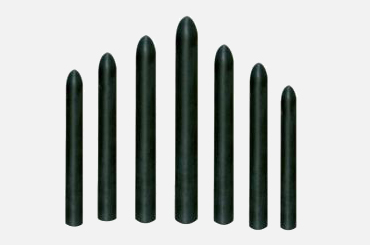

Product Details

Tundish stopper is one of the important steel flow regulation components, stoppers are designed to cope with the extreme thermal shock lining when regulating the molten steel flowing into the mould. The head of our stoppers is specially engineered to withstand erosion by molten steel. The slagline is also strong enough to withstand possible chemical corrosion caused by tundish immersion. we apply different mixtures of aluminia or magnesia to the head of our stoppers to enabling them to cast various types of steel.

Features

- Argon injection structure depending on customer specifications.

- Ceramic glaze layer to prevent the material oxidation effectively.

- Ceramic fiber blanket to prevent heat lost during casting.

- High quality AL-C materials having high corrosion and thermal shock resistance.

- High quality Zr-based composite to provide high corrosion resistance at the slag line.

- Non-graphite based materials to meet the requirements of producing low carbon steel, silicon steel and high purity steel

- Good erosion resistance

- Anti-erosion performance

- Stable flow control during casting

Applications

steel ladle,refining ladle,electric furnace refining ladle,tundish

Physical And Chemical Indicators

| Brand Properties |

Tundish Stopper | |||||||

| Body | Slag Line | Head | ||||||

| Chemical Composition (%) | Al2O3 | 53.28 | — | 86.61 | 71.43 | 15.1 | ||

| Fe2O3 | 0.91 | — | 0.43 | 0.91 | — | |||

| SiO2 | 14.48 | — | 0.77 | 10.65 | 8.95 | |||

| TiO2 | 1.41 | — | 0.33 | — | — | |||

| ZrO2 | — | 75.1 | — | — | 0.29 | |||

| CaO | — | 1.71 | — | — | 1.56 | |||

| MgO | — | — | — | 5.71 | 56.8 | |||

| LOI (%) | 30.59 | 15.01 | 11.11 | 10.95 | 17.3 | |||

| Bulk Density (g/cm3) | 2.42 | 3.78 | 2.85 | 2.78 | 2.59 | |||

| Apparent Porosity (%) | 14.3 | 15.61 | 17.7 | 17.7 | 16.7 | |||

| Fracture Strength (MPa) | 8.4 | 6.97 | 6.73 | 6.73 | 7.8 | |||

| Main Application | Ladle & Tundish | |||||||

Picture:

Hot Tags: tundish stopper, suppliers, price, buy, for sale

Inquiry Form